Ngowe-1889 eUnited States, xa isibulali-ntsholongwane sangaphambi kotyando sasinemercuric chloride necarbolic acid (phenol), umongikazi ogama linguCarolyn, waphathwa sisifo sesikhumba ngenxa yokusetyenziswa kwexesha elide.

Kwenzeka ukuba ugqirha awayesebenzisana naye wayethandana naye waza wayalela uGoodyear Rubber ukuba akhe iiglavu zelatex ezicekethekileyo ukukhusela izandla zesithandwa sakhe, kwaye kwaveliswa iiglavu zelatex ezilahlwayo, kwaye namhlanje, ngaphezu kweminyaka eli-100 kamva, iiglavu zelatex zisetyenziswa abasebenzi bezempilo kwihlabathi liphela.Ndimele nditsho ukuba olu luyilo olukhulu kakhulu.

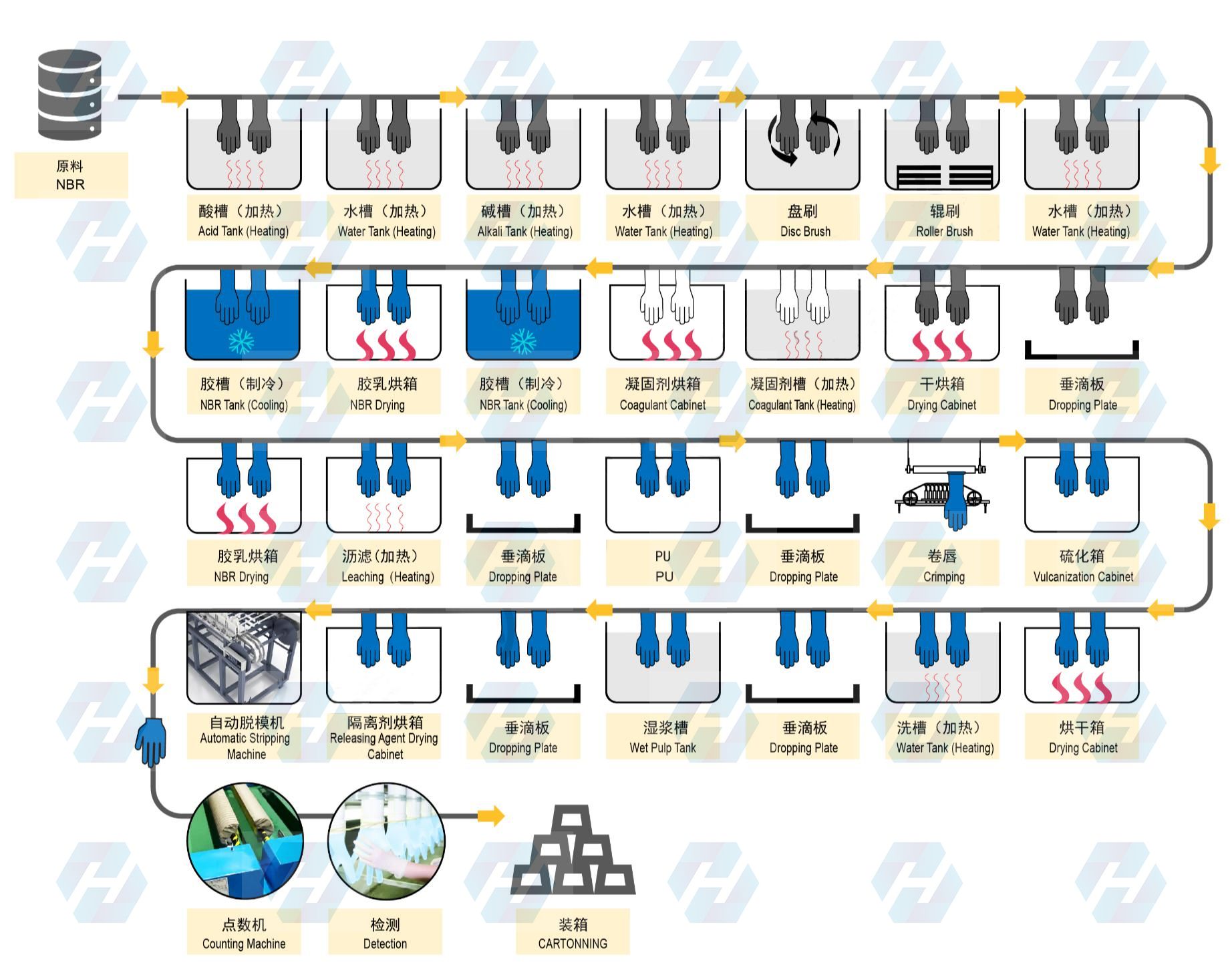

Ukwenziwa kweeglavu ze-latex kufuna ukusetyenziswa kwenani elikhulu kakhulu lokubumba kwezandla ze-ceramic, kwaye naziphi na iincinci ezincinci ezishiywe phezu kwendawo yokubumba zingabangela imingxuma kwiiglavu kwaye zivelise iimveliso eziphosakeleyo, ngoko ke iimbumba kufuneka zicocwe kakuhle.Kufuneka icocwe ngamanzi anesepha, iblitshi, iibrashi kunye namanzi ashushu phambi kokuba umsebenzi wokulungiselela ugqitywe.

1. Nitshintshane nidlule kwitanki yeasidi, itanki yealkali, kunye nokucoca itanki yamanzi

Isetyenziselwa ukulahla intsalela yexesha lokugqibela ukwenza iiglavu zerabha, kunye nokucoca ngelixa ujika, kunokunyusa amandla okucoca.

2. Ukucoca i-disc brush kunye ne-roller brush

Kwanemingxuma yeminwe ayinakuthintelwa ukucocwa ngokucokisekileyo.

3. Ukucoca amanzi ashushu

Inxalenye yokugqibela yentsalela nayo ihlanjwe kunye, emva kokucoca amaxesha amaninzi, i-porcelain hand mold iye yacoceka kakhulu, ayishiyi nakuphi na ukungcola.

4. Ithontsi ejingayo yomile

Vumela ukubumba kwezandla zome kancinci, eli nyathelo yinkqubo yokomisa ngelixa uvuza amanzi.

5. Ukuhlamba ngamanzi ekhemikhali

I-latex ye-liquid ayikwazi ukudibaniswa ngokuthe ngqo kwi-ceramic, ngoko ke i-coating yekhemikhali kufuneka ifakwe kumphezulu we-mold yesandla kuqala.

6. Ukwaleka kweLatex

Xa isikhunta sesandla sifakwe kwi-latex liquide efudumeleyo, i-chemical coating kunye ne-latex iya kusabela kwaye ibe yi-gel-efana ne-gel, igubungele ngokupheleleyo umphezulu we-mold yesandla kunye nokwenza ifilimu ye-latex.

7. Ukomisa i-latex

Nangona ukoma kwi-oven, iimbumba zezandla kumgca wendibano zijikelezwa ngokuqhubekayo ukwenzela ukusabalalisa i-latex ngokulinganayo kunye nokuphepha ukuqokelela.

8. Ukuqengqeleka imiphetho ngebrashi

Phambi kokuba i-latex yomelele ngokupheleleyo, sebenzisa iibhrashi ezininzi ezineengile ethambekileyo ukuhlikihla iiglavu zelatex kancinane ngexesha kwaye ngokuthe ngcembe uqengqele imiphetho yeglavu nganye yelatex.

9. Ukususa iiglavu

Emva kwesinyathelo se-hemming, iiglavu ze-latex zilungile.

10. Uvavanyo lokwelula nokunyuka kwamaxabiso

Olu luvavanyo ekufuneka lujongwe yiglavu nganye yelatex.

11. Isampuli kunye novavanyo lokuzaliswa

Isampulu yeeglavu ze-latex ezivela kwibhetshi yokuvelisa ziya kuvavanywa ukuzaliswa kwamanzi, kodwa ukuba kukho nanye yazo iyasilela, yonke ibhetshi iya kuba ingavumelekanga.

Umgca wokuvelisa umfanekiso wenxalenye

Iiglavu zelatex ezilahlayo zohlulwe ngokwala manqanaba mathathu alandelayo.

1. kakhulu esetyenziswa kushishino lokutya kunye powder elahlwa iiglavu latex, inkqubo imveliso kuyimfuneko ukujoyina ukuphepha iiglavu ukunamathela kunye, ukuze kube lula ukunxiba.Ingqwalasela ekhethekileyo kufuneka ihlawulwe kwinto yokuba kukho umgubo wombona olungileyo kunye nombi.Sisebenzisa umgubo wombona womgangatho otyiwayo, kungenjalo ayilunganga kumsebenzisi, kunye nento ekufuneka yenziwe.

2. Iiglavu ze-latex ezilahlwayo ezingenapowder zisetyenziswa kakhulu kwi-electronics kunye namashishini ezonyango, kuba ziveliswa nje ngomgubo, emva kokucoca kwethu ngamanzi okucoca kunye nokuphuma kweeglavu ze-latex ezingenayo umgubo.

I-3.Iiglavu ze-latex ezihlanjululwayo ezihlambulukileyo ezisetyenziswa kakhulu kwi-electronics echanekileyo kunye namashishini ezonyango, ezenziwe ngeeglavu ze-latex ze-latex ezingenamgubo eziye zahlanjululwa ngamanzi kwaye zahlanjululwa kwakhona ngeklorini, kunye nococeko lwamanqanaba aliwaka.

Ixesha lokuposa: Dec-01-2021